Storage Bin Inspection Using the Elios 3 at a Mine

How can drones improve the safety and efficiency of inspecting storage bins? MIS Aero demonstrated the benefits of using the Elios 3 drone during an inspection project for a leading mining client in Oman, showcasing its capabilities effectively.

Key Benefits at a Glance

|

Speed The Elios 3 allowed inspectors to complete the job in just 4 days instead of the usual 15. This significantly reduced the time required for the entire process. |

Safety By eliminating the need to enter confined spaces, the Elios 3 kept the team safe from risks like high dust levels and working at height. |

|

Data Quality MIS Aero provided full 3D models of the storage bins, including key points of interest. This made maintenance planning much more efficient. |

Access The Elios 3 could access multiple entry points and reach every part of the bin’s interior. Its maneuverability ensured thorough and accurate inspections. |

Safe mining operations go beyond just caves and quarries—they also include the equipment and materials used in daily processes. Maintaining critical assets like storage bins and crushers is essential for both safety and operational efficiency.

However, inspecting certain structures, such as large storage bins, can be extremely challenging. High elevation, heavy dust, and limited visibility often make traditional methods risky and time-consuming. A mine in Oman wanted to find a safer and faster way to inspect their storage bins.

What Is a Standard Storage Bin Inspection?

A mining company in Oman needed internal visual inspections of their storage bins to detect any damage or defects in the polyethylene lining inside the tanks. Traditionally, this involved rope access, which posed significant risks due to height, dust, and confined spaces.

The previous inspection process took between 10 to 15 days, which was inefficient and unsafe. The mine operator sought a better solution—one that would reduce risk and speed up the process.

The storage bins, standing at 40 meters, are difficult to inspect without additional equipment

The storage bins, standing at 40 meters, are difficult to inspect without additional equipment

Drone Inspections with the Elios 3

MIS Aero, a trusted service provider in the region, was tasked with finding a safer and more efficient alternative. With experience in both internal and external inspections, they recently integrated AI into their services and became the sole owner of the Elios 3 in Oman through their partner SIGMA Enterprises.

MIS Aero focused on reducing risk while improving efficiency. They planned to use the Elios 3 to inspect the interior of the storage bins without requiring personnel to enter them, allowing for faster data collection and safer operations.

The Elios 3 flying back down to the inspectors

The Elios 3 flying back down to the inspectors

Planning Flights Inside Storage Bins

The Elios 3 is specifically designed for confined space inspections. Its ability to collect LiDAR and visual data simultaneously makes it ideal for navigating dusty and complex environments like storage bins.

The MIS Aero team created custom flight plans to cover all seven 40-meter-tall bins. They used multiple entry points and range extenders to ensure full coverage without the need for human entry. They also worked closely with the mine team to identify potential obstacles, ensuring safe and effective flights.

The pilot and inspector look for points of interest during the flight

The pilot and inspector look for points of interest during the flight

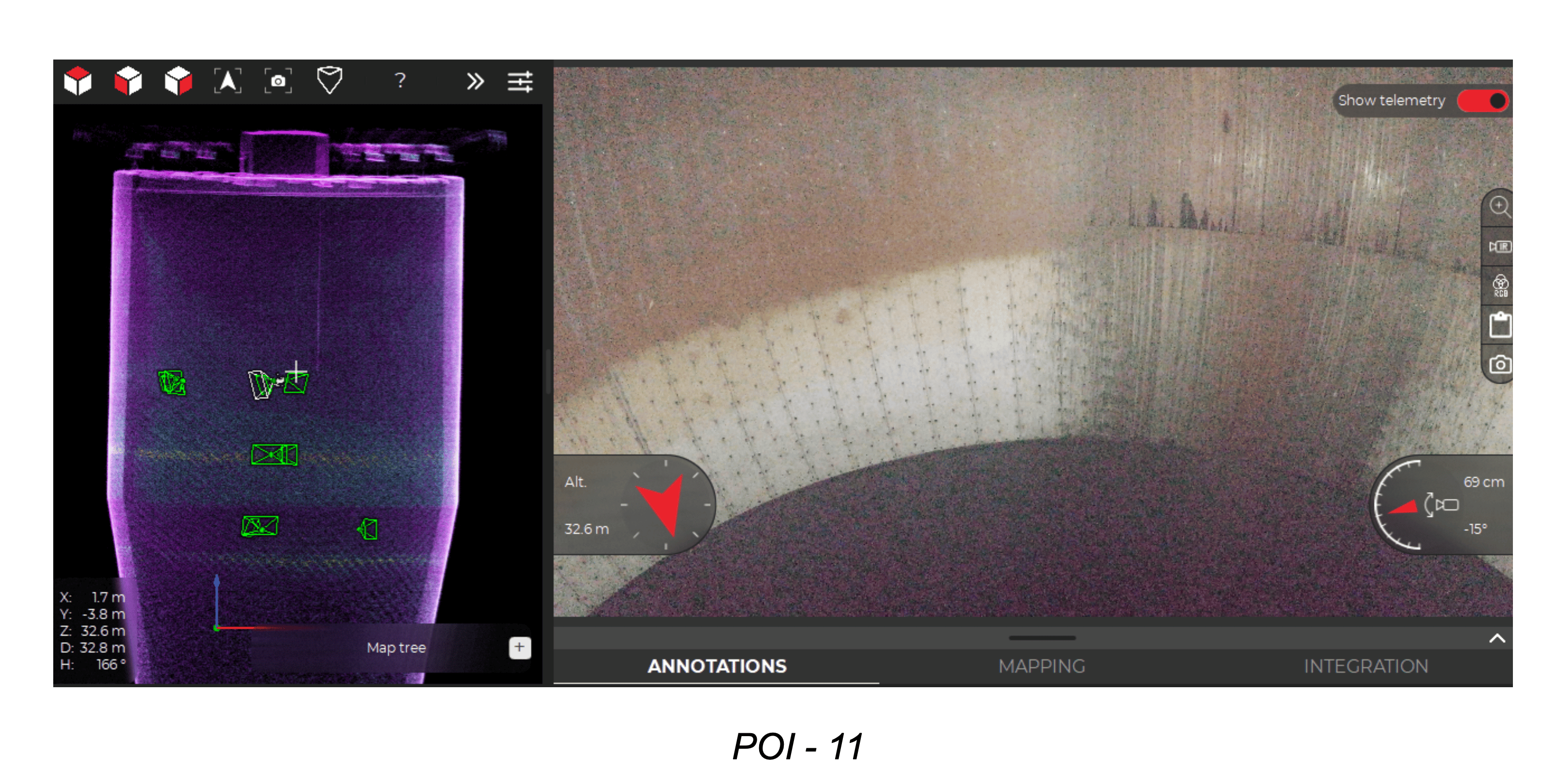

After completing the flights, all data was processed using Inspector 4 to generate a detailed report for the client. The report met all expectations, especially the geolocation of points of interest within the 3D point cloud.

This feature made it easy for engineers and maintenance teams to plan repairs and communicate more effectively. Everyone could visualize the issues and coordinate their work more efficiently.

Setting a New Standard for Storage Bin Inspections

The mine's decision to adopt innovative technology, combined with MIS Aero’s expertise, led to a safer and much faster inspection process. By eliminating unnecessary rope access, the project reduced downtime and improved site operations overall.

The LiDAR scan includes points of interest (POI) identified by inspectors during the flight, allowing for precise comparison with photos taken by the Elios 3

This successful project marked the first of its kind in Oman and opened new opportunities for MIS Aero. It demonstrated the real value of drone-based inspections and paved the way for future collaborations. As the mining industry continues to evolve, adopting advanced technologies like the Elios 3 will be key to safer, smarter, and more efficient operations.

Aluminum Profiles are more and more used in the production of doors and windows being their advantages such as light weight, high strength, corrosion resistance, and high cost performance. In addition, aluminum windows and doors have various styles and easy to install. It is an excellent choice for doors and windows of modern buildings.

Aluminum Extrusion Manufacturers In Usa,Aluminum Extrusion Usa,Aluminium Extrusion Usa,2080 Aluminum

Foshan Knilex Aluminum Co., Ltd. , http://www.aluprofilefactory.com