Understanding Self-Dumping Hoppers: Efficiency, Safety, and Applications

By Mike Nelson, Posted in Forklift Attachments

In the fast-paced world of material handling, efficiency and safety are more important than ever. One tool that has made a big impact across various industries is the self-dumping hopper. These versatile units are widely used in construction, manufacturing, agriculture, and waste management, helping streamline operations and improve productivity. Let’s take a closer look at what self-dumping hoppers are, how they work, and why they’re so valuable.

What Are Self-Dumping Hoppers?

Self-dumping hoppers, sometimes called self-dumping bins or containers, are designed to make the process of loading and unloading materials much easier. Made from durable materials like steel, these hoppers feature a unique mechanism that allows them to automatically release their contents when triggered. This eliminates the need for manual labor, making them ideal for heavy-duty applications.

Benefits of Self-Dumping Hoppers

The main advantage of using self-dumping hoppers is the boost in efficiency they provide. They simplify material handling by reducing the time and effort needed for loading and unloading. A single operator can manage tasks that would otherwise require multiple workers, which leads to significant labor cost savings.

Safety is another major benefit. By automating the unloading process, self-dumping hoppers reduce the risk of injuries associated with manual labor. Operators can stay at a safe distance from potential hazards, lowering the chances of workplace accidents. Additionally, these hoppers are highly adaptable, working well with a wide range of materials—such as construction debris, bulk solids, recyclables, and agricultural products—and can be paired with forklifts, cranes, or other machinery.

Types of Self-Dumping Hoppers

There are several types of self-dumping hoppers available, each suited for different needs. Standard hoppers are great for general use, while low-profile models are designed for areas with limited overhead space. Specialty hoppers are custom-built for specific materials or applications, offering even more flexibility.

How Self-Dumping Hoppers Work

Operating a self-dumping hopper is simple. Materials are loaded into the hopper either manually or with equipment like forklifts or front loaders. Once it's full, the hopper is moved to the desired location, and a lever is pulled to tilt it forward, releasing the contents. This streamlined process makes it easy to handle large volumes of material quickly and efficiently.

Applications and Use Cases

Self-dumping hoppers are used across a variety of industries. In construction, they're perfect for removing debris and transporting materials on busy job sites. In manufacturing, they help manage waste and move raw materials between production areas. Farmers use them for handling grain and distributing feed, while waste management companies rely on them for efficient collection and disposal. Recycling centers also benefit from their ability to sort and transport recyclable materials, supporting eco-friendly practices.

Choosing the Right Self-Dumping Hopper

Selecting the right hopper depends on several factors, including the type and weight of materials you'll be handling, the required capacity, the working environment, and any safety features you may need. Consulting with an expert can help ensure you get the best solution for your operation.

Maintenance and Safety Tips

To keep your self-dumping hopper in top condition and ensure safe operation, regular maintenance is essential. Inspect components regularly, replace worn parts promptly, and train operators on proper usage and safety procedures. Taking these steps will help extend the life of your equipment and prevent accidents.

Comparisons with Alternative Solutions

Compared to manual handling or traditional containers, self-dumping hoppers offer clear advantages. They increase efficiency, save labor costs, and provide customizable options to suit different operational needs. For businesses looking to improve productivity and reduce risks, these hoppers are a smart investment.

Self-dumping hoppers have transformed the way materials are handled across many industries. Whether you're involved in construction, manufacturing, agriculture, or waste management, these tools can help you work smarter, not harder. If you're interested in integrating self-dumping hoppers into your workflow, reach out to us for guidance and high-quality solutions.

How Much Does Our Self-Dumping Hopper Cost?

At Koke Inc., we specialize in building self-dumping hoppers tailored to meet individual customer needs. Each unit is manufactured to order, meaning the price varies depending on size, features, and quantity. We offer personalized quotes over the phone, so don’t hesitate to contact us at 800.535.5303 or visit our website for more details. Let us help you find the right solution for your business.

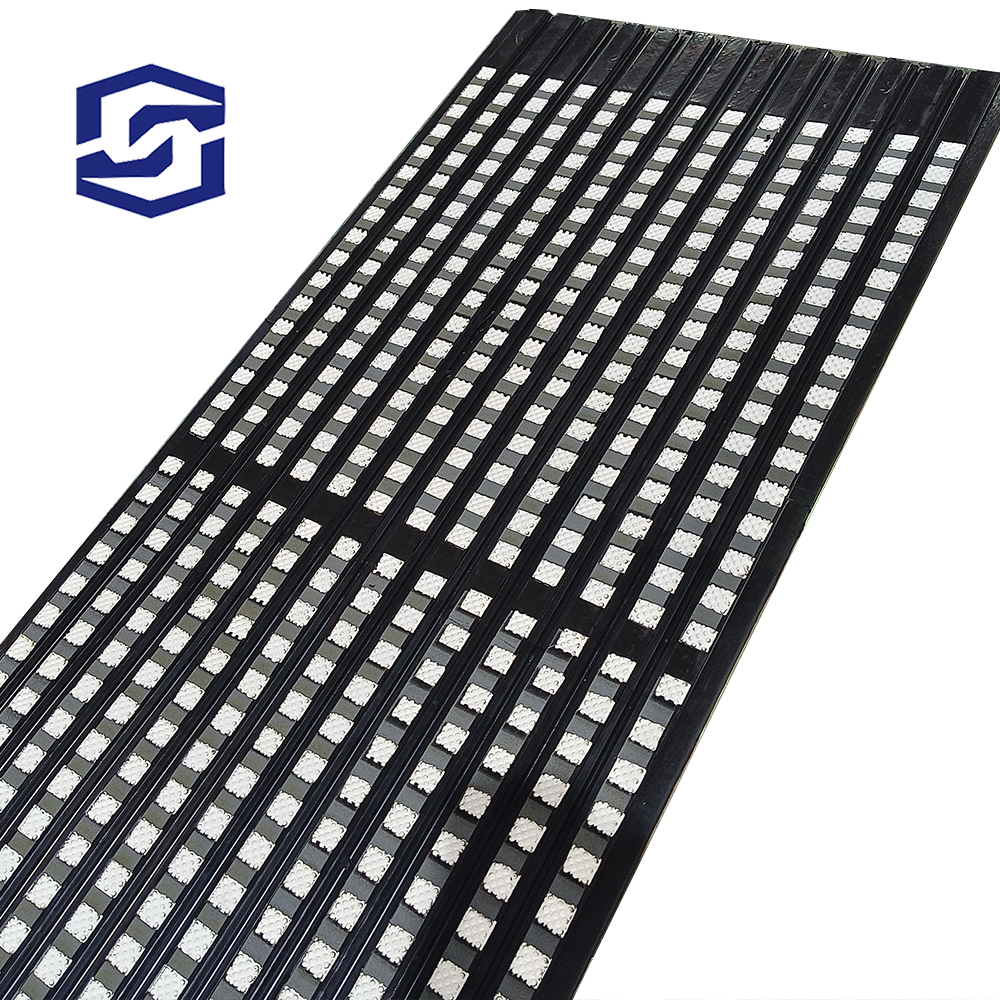

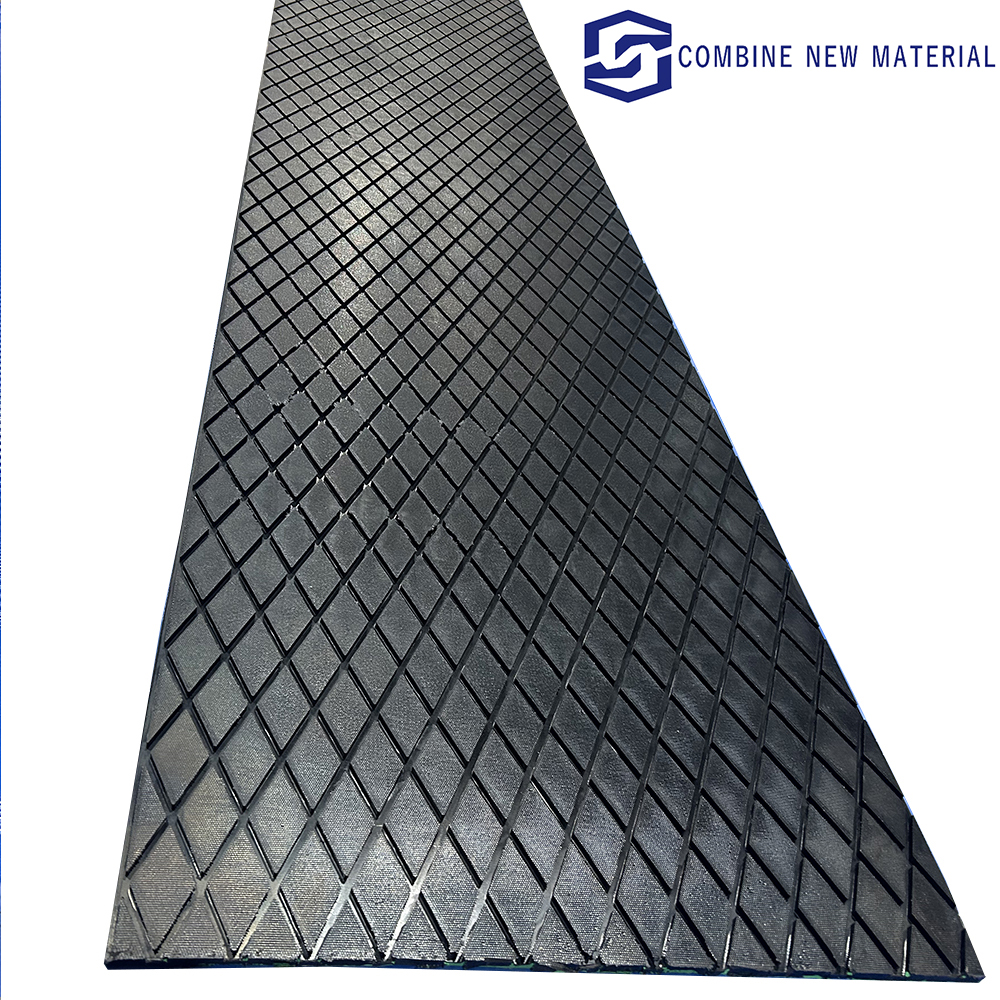

pulley lagging,rubber sheet,wear resistant,ceramic rubber sheet,Three-in-one impact resistant ceramic composite liner

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com