What Is Backfilling in Mining?

Backfilling is the process of refilling an excavated space, typically after mining activities have removed valuable minerals. This practice is widely used in both construction and the mining industry, where it plays a crucial role in maintaining stability and safety.

In underground mining, backfilling is essential for supporting the surrounding rock mass, preventing surface subsidence, reducing ore dilution, and creating a safer environment for miners. It also helps manage waste materials by using them as part of the backfill, which can significantly reduce the environmental impact on the surface.

[Note: The term "backfilling" is sometimes written as "back filling," but the former is more commonly used today.]

Types of Backfill

Backfill materials are usually derived from waste generated during the extraction of target minerals, known as tailings. These materials are then processed and used to fill voids left behind after mining operations.

Backfilling in underground mines—a truck hauling ore

Backfilling in underground mines—a truck hauling ore

There are several common types of backfill used in mining:

- Cemented backfilling: This involves mixing tailings with cement to create a strong, cohesive material that fills voids effectively. It’s ideal when only small amounts of cement are needed due to its high cost.

- Dry rock backfilling: Composed of dried tailings, gravel, or rock waste, this method is often used in cut-and-fill mining techniques.

- Hydraulic sand backfilling: Fine sand is separated from tailings and used as backfill, often pumped into mine voids. It can be mixed with binding agents if necessary.

- Paste backfilling: Commonly used in coal mines, this method involves mixing solid tailings with water and binding agents to form a paste-like material suitable for filling stopes.

The Mine Backfilling Process

The backfilling process varies depending on the type of mine, the nature of the tailings, and the location of the stope or void. In most cases, heavy machinery is used to pump the backfill material into place. For shallow mines, gravity and dump trucks may be sufficient.

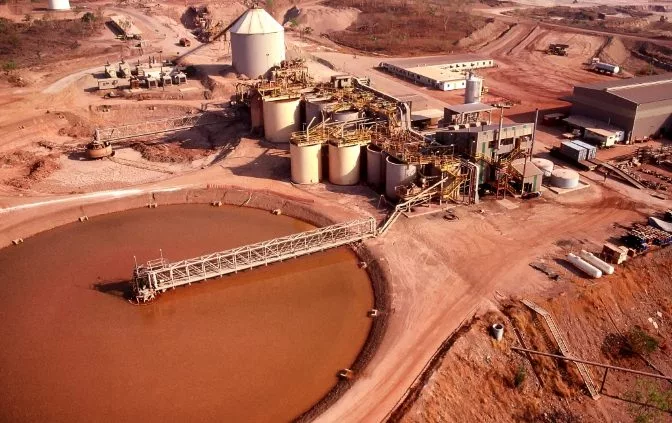

Tailings plant

Tailings plant

Most underground mines use cemented paste backfill, which is processed at the surface before being transported underground. Tailings are filtered to remove excess water, and binders are added to ensure structural integrity. High-pressure pumps deliver the mixture to the mine, while barricades or bulkheads help contain the material during curing.

Mine Backfilling Process Hazards

While backfilling is essential, it also comes with several risks and challenges. Here are some of the most common hazards associated with the process:

- Backfill segregation: Coarse and fine particles can separate during curing, leading to uneven distribution and potential instability.

- Backfill sloughing: A previously cured layer may break down, causing fresh backfill to shift or collapse.

- Borehole clogging: Material can get stuck in boreholes, requiring additional drilling to access the mine.

- Bulkhead failure: If the structure retaining the backfill fails, it can lead to dangerous collapses.

- Pipe hammering: Sudden pump shutdowns can cause pressure surges, damaging pipelines.

- Pipeline burst: Overpressure or blockages can result in ruptured pipes, causing delays and safety issues.

- Plugged pumps: Pumps used for transporting backfill can become clogged over time, affecting efficiency.

- Plugged sump: Debris from backfilling can block ventilation systems, requiring cleaning and maintenance.

- Pump failure: Frequent use and blockages can lead to mechanical breakdowns.

Advantages and Disadvantages of Backfill Mining

Backfill mining offers numerous benefits but also presents some challenges. It is a widely adopted technique due to its ability to improve safety, support structures, and reduce environmental impact. However, it also requires significant investment and careful planning.

Advantages of Backfill Mining

- Improves mine stability and safety.

- Enables extraction of remaining minerals in pillars during room-and-pillar mining.

- Reduces the risk of rock bursts and roof falls.

- Minimizes groundwater contamination when binders are used.

- Enhances mine ventilation.

- Helps prevent acid rock drainage (ARD).

- Reduces the need for surface waste storage.

- Lowers environmental impact upon mine closure.

- Prevents mine collapse after pillar extraction.

Disadvantages of Backfill Mining

- Requires expensive pumping systems for high-density tailings.

- Demands an independent tailings processing facility.

- Needs additional labor and equipment management.

- Can be costly when using binders like cement.

- May slow down the overall mining process.

- Increases risk of liquefaction under certain conditions.

- Can lead to groundwater contamination if not properly managed.

- Requires dewatering, increasing operational costs.

An inclined bed CNC machine offers several advantages over a flat bed CNC machine. Here are the key advantages:

-

Enhanced Rigidity: The inclined bed design provides better structural rigidity. The inclined angle increases the machine's natural stability, reducing vibrations during machining operations. This enhanced rigidity improves machining precision, accuracy, and surface finish quality.

-

Improved Chip Evacuation: With an inclined bed, chips and coolant can flow naturally away from the workpiece, aiding in efficient chip evacuation. This reduces the risk of chip recutting, minimizes tool wear, and improves overall machining performance.

-

Accessibility and Visibility: The inclined bed design allows operators to have better access to the workpiece and improved visibility of the machining process. This makes it easier to set up, monitor, and adjust machining operations, enhancing productivity and reducing errors.

-

Compact Footprint: Inclined bed CNC machines typically have a smaller footprint compared to flat bed machines. This saves valuable floor space in the workshop, allowing for better layout optimization and efficient use of available area.

-

Ergonomics and Operator Comfort: The inclined bed design reduces the need for operators to bend or reach over the machine, promoting better ergonomics and reducing the risk of strain or injury. It offers improved operator comfort and ease of operation.

-

Chip Management: The inclined bed design facilitates efficient chip management. Chips can be easily collected and removed, reducing the risk of chip buildup, minimizing maintenance requirements, and prolonging tool life.

-

Tool Life and Performance: The enhanced rigidity and stability of an inclined bed CNC machine result in reduced tool deflection and improved cutting performance. This leads to increased tool life, better machining efficiency, and cost savings in terms of tool replacement and downtime.

-

Versatility: Inclined bed CNC machines are versatile and can handle various machining operations, including turning, milling, drilling, and tapping. They can effectively machine a wide range of materials, from metals to plastics, allowing for diverse applications in different industries.

Inclined Bed Cnc Machine,High Rigid Inclined Cnc Bed Machine Tools,Inclined Body Bed Cnc Lathe,Inclined Flat Bed Cnc Machine

Ningbo Leyan Machinery Technology Co., Ltd , https://www.cncleyan.com