Centrifugal Wheelblast vs. Air Blasting: Which One Suits Your Needs?

Updated: October 17, 2023When it comes to abrasive blasting, choosing the right method can make a big difference in efficiency, cost, and finish quality. Whether you're working with small components or large industrial parts, both wheel blasting and air blasting have their own unique advantages. But which one is best for your specific application? Let's break down the key differences and help you decide.

Both wheel blasting and air blasting use abrasive media to clean, etch, or prepare metal surfaces. However, the way they deliver the media varies significantly. The choice between the two often depends on factors like part size, production volume, and the desired finish. Understanding these differences will help you optimize your process and get the best results.

If you're unsure whether to go with wheel blasting or air blasting, this guide will walk you through the pros and cons of each method so you can make an informed decision.

Contact Us

What Is Wheel Blasting?

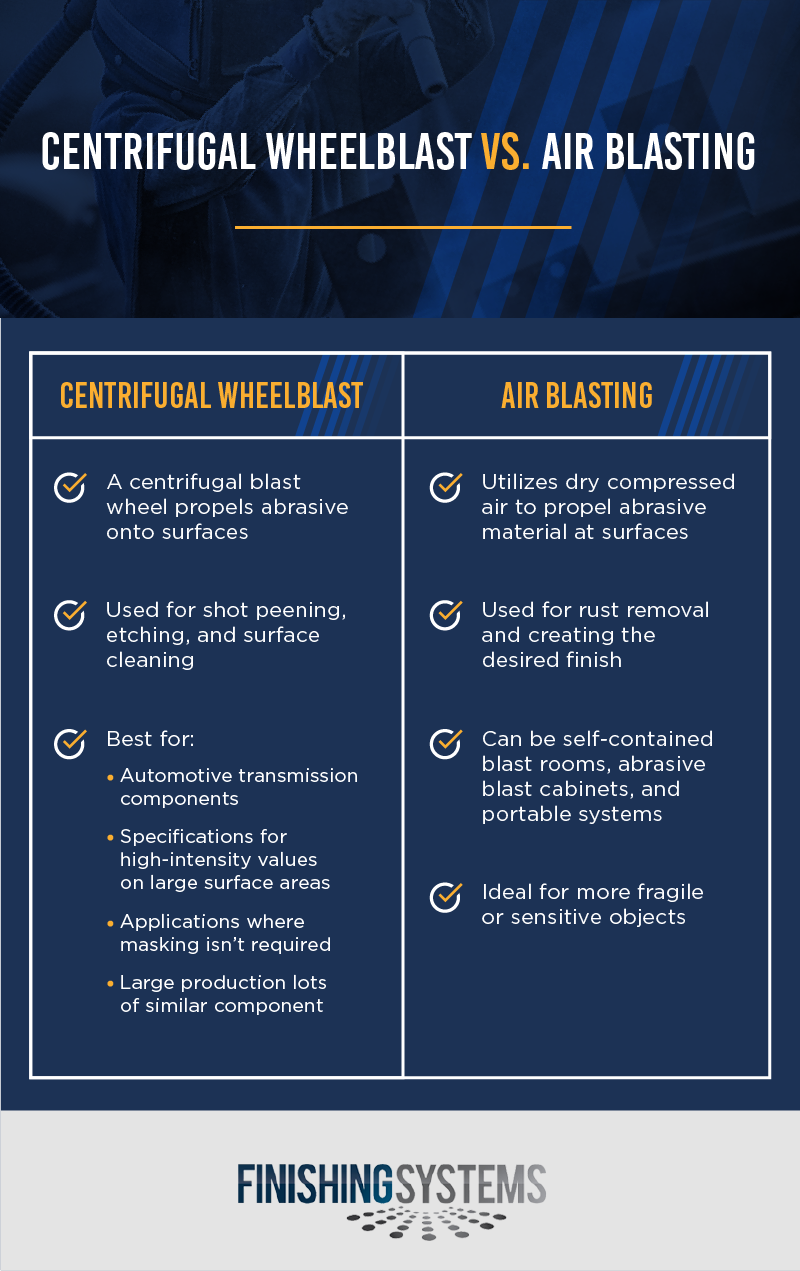

Wheel blasting uses a high-speed centrifugal blast wheel to propel abrasive media onto the surface of your parts. This method is ideal for heavy-duty applications where speed and coverage are important. It’s commonly used for tasks like shot peening, surface cleaning, and etching.

Compared to air blasting, wheel blasting delivers a much higher volume of abrasive material in a shorter amount of time. The system typically includes a drive mechanism—either belt-driven or direct-driven—that controls the speed of the blast wheel. Modern systems often feature variable frequency drives (VFDs) for precise control over the blasting cycle.

Wheel blasting is particularly well-suited for large, durable components such as automotive transmission parts, railway components, and structural steel. It’s also great for high-volume production runs where consistent, even coverage is required.

- Perfect for large, heavy components like gears, shafts, and axles

- High efficiency for large surface areas and high-intensity applications

- Effective for batch processing without the need for masking

- Best for metallic abrasives like steel shot, grit, or wire

The process involves loading parts into a chamber, where the blast wheel throws abrasive at high speed. This ensures that all surfaces are evenly treated. Because of its speed and capacity, wheel blasting is often more cost-effective for large-scale operations.

What Is Air Blasting?

Air blasting uses compressed air to propel abrasive media onto the surface of your parts. This method is highly versatile and is often used in applications where precision and control are needed. It’s ideal for smaller parts, delicate components, or situations where only a portion of the part needs treatment.

There are several types of air blasting systems, including self-contained blast rooms, cabinet systems (both direct pressure and suction types), and portable units. These systems are designed to handle different materials and provide efficient dust collection for a cleaner working environment.

One of the main benefits of air blasting is its flexibility. You can easily adjust the pressure, media type, and nozzle angle to achieve the desired finish. It’s also a good option when you need to avoid damaging sensitive or thin-walled parts.

How to Choose Between Wheel Blasting and Air Blasting

Choosing between wheel blasting and air blasting depends on your specific needs. Here are some key considerations:

Wheel blasting is faster and more efficient for large, robust parts. It’s ideal for high-volume production and offers better cost-effectiveness for larger objects. On the other hand, air blasting provides greater control and is better suited for delicate or complex parts that require careful treatment.

If you’re dealing with fragile items or need to target specific areas, air blasting is usually the safer choice. It allows for more precise application and easier adjustment of the blasting parameters.

Let Finishing Systems Help You Decide

If you're still unsure which blasting method is best for your operation, or if you're looking to invest in equipment, Finishing Systems is here to help. We offer a wide range of blasting solutions, from wheel blasting machines to air blasting cabinets, and we can help you find the perfect setup for your needs.

Whether you're looking to improve your production efficiency, reduce costs, or achieve a specific surface finish, our team has the expertise to guide you every step of the way.

To learn more about how we can support your blasting and finishing processes, contact us today.

Pressure Washers And Accessories

Floor cleaners are also called floor scrubbers, which are suitable for cleaning hard and weak floors such as cement, granite, marble, ceramics, slate, ceramic tiles, PVC, and wear-resistant floors in the work area. It is mainly divided into two types: hand-push floor Cleaning Machine and driving type floor cleaning machine.

1. What is the function of the floor scrubber?

Floor scrubber is a cleaning equipment often used in the cleaning industry

2. Which operating areas is the floor scrubber suitable for?

Hospitals, schools, shopping malls, supermarkets, hotels, stores, waiting rooms, plazas, etc.

3. How to divide the types of scrubbers?

According to the scrubber; in accordance with the scrubber; in accordance with the diversity of functions, there are multifunctional scrubbers.

4. Advantages of Washing Machine

Simple and easy to operate; low maintenance cost; high efficiency, better cleaning effect; saving consumables, labor costs, time (6-40 times faster than manual speed); cleaning large areas, creating profits, and saving costs;

5. What are the main problems that the floor scrubber solves?

Health and hygiene issues; environmental protection issues; thoroughly clean the ground; avoid possible personal injury; do not need to close any passages or areas during cleaning.

Pressure Washers And Accessories,Pressure Washers Accessories,Pressure Washers Accessory,Power Washer Accessory

Ningbo Senmiao Trading Co., Ltd. , https://www.nbsenmiao.com