Centrifugal Wheelblast vs. Air Blasting: Which One Suits Your Needs?

Updated: October 17, 2023When it comes to abrasive blasting, choosing the right method can make a big difference in efficiency, cost, and finish quality. Whether you're dealing with small components or large industrial parts, both wheelblasting and air blasting have their own unique advantages. But how do you know which one is best for your specific application?

Both methods use abrasive media to clean, etch, or peen metal surfaces. However, the choice between them often depends on factors like part size, shape, production volume, and the desired finish. Understanding the differences between these two techniques can help you optimize your process and achieve the best results.

If you're trying to decide when to use wheelblasting versus air blasting, this guide will walk you through the key considerations to help you make an informed decision.

Contact Us

What Is Wheel Blasting?

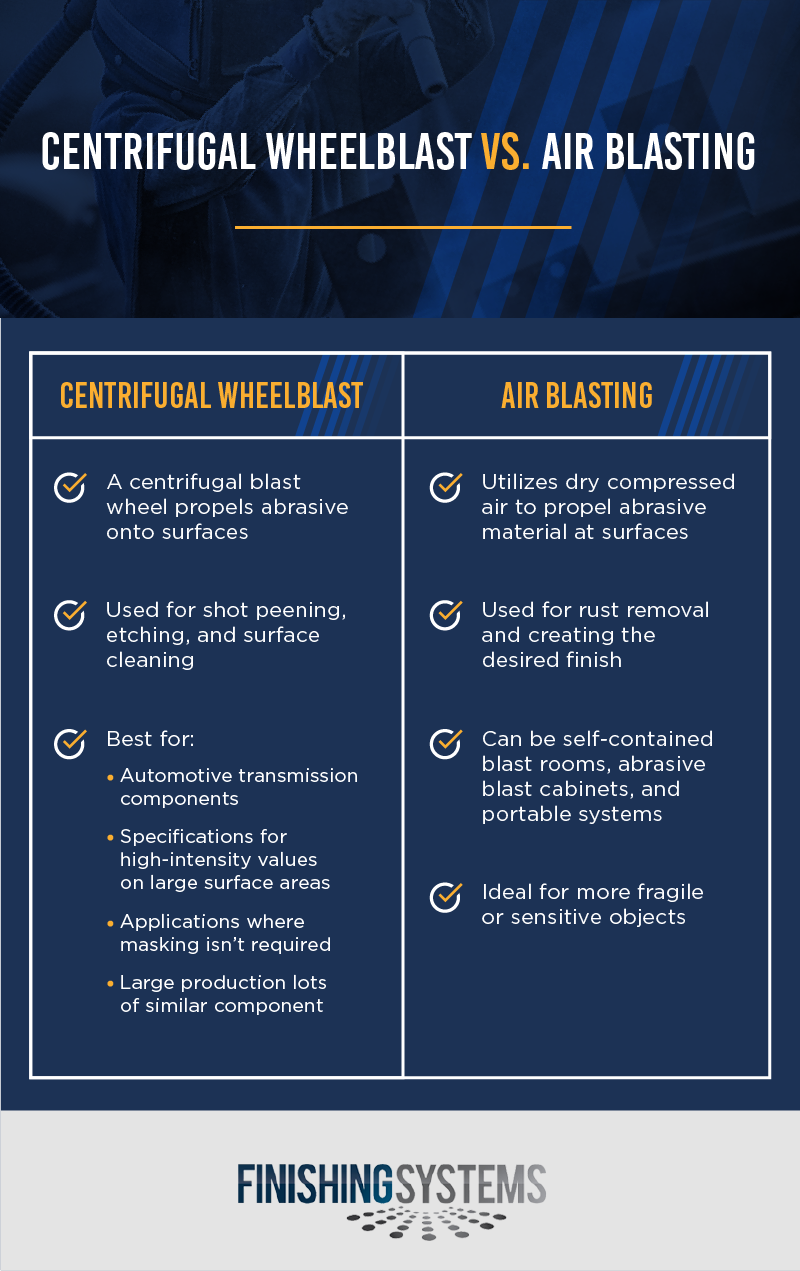

Wheelblasting is a high-speed process that uses a centrifugal blast wheel to propel abrasive media at high velocity onto the surface of metal parts. This method is commonly used for tasks such as shot peening, surface cleaning, and etching. The blast wheel rotates rapidly, creating a powerful and even distribution of media across the entire surface of the part.

Compared to air blasting, wheelblasting delivers a much higher volume of abrasive material in a shorter time. The speed of the blast wheel—whether direct-driven or belt-driven—can be adjusted using a variable frequency drive (VFD), allowing for greater control over the process. This makes wheelblasting ideal for high-volume, repetitive applications where time and efficiency are critical.

Wheelblasting is particularly well-suited for:

- Automotive transmission components such as shafts, gears, leaf springs, and axle beams

- Railway parts and large structural components

- Applications requiring full surface treatment without masking

- Large batches of similar parts

The process typically involves loading a batch of parts into the chamber, while abrasive media (such as steel shot, grit, or aluminum cut wire) is introduced into the system. The blast wheel then evenly distributes the media across all surfaces, ensuring consistent and efficient finishing. This method is especially effective with metallic abrasives and is often more cost-effective for larger parts.

What Is Air Blasting?

Air blasting, on the other hand, uses compressed air to propel abrasive media onto the surface of a part. This method offers greater flexibility and precision, making it ideal for delicate or complex components. It’s commonly used for rust removal, surface preparation, and achieving specific finishes.

Air blasting systems come in various forms, including self-contained blast rooms, blast cabinets (either pressure or suction type), and portable units. These systems allow for controlled environments and efficient dust collection, ensuring a cleaner and safer workspace.

One of the main benefits of air blasting is its ability to handle smaller or more intricate parts with care. It also provides better control over the intensity and direction of the blast, which is essential for sensitive materials or detailed work.

How to Choose Between Wheelblasting and Air Blasting

Deciding between the two methods depends largely on your specific needs. If you're working with large, robust parts and need high throughput, wheelblasting is likely the better option. It's faster, more cost-effective, and ideal for high-intensity applications.

However, if you're dealing with smaller, fragile, or irregularly shaped parts, air blasting may offer more precision and control. It's also a good choice when only a portion of the part needs treatment, or when masking is required.

Ultimately, the right choice depends on your production volume, part complexity, and desired finish. In many cases, combining both methods can yield the best results.

Work With Finishing Systems to Find the Right Solution

If you're still unsure about which method suits your operation best, or if you're looking to invest in blasting equipment, Finishing Systems can help. We offer a wide range of blasting systems, media, and support to ensure you get the perfect solution for your needs.

Whether you're looking to improve efficiency, reduce costs, or achieve a superior finish, we're here to guide you every step of the way. Contact us today to learn more and find the best option for your business.

Ningbo Senmiao Trading Co., Ltd. , https://www.nbsenmiao.com