Pump surfaces, including the inner surface of the pressure chamber (also known as the volute), may develop uneven rust over time. If the surface becomes rough, it can significantly reduce the pump's efficiency by 7% to 8%. During maintenance, it's recommended to smooth out the affected areas using a steel brush, iron sandpaper, or a grinding wheel. This simple repair can help reduce fuel consumption or power usage by 9% to 14%, improving overall performance and saving energy in the long run. Regular inspection and timely cleaning of these components are essential to maintaining optimal pump operation and extending its service life. Keeping the internal surfaces smooth not only enhances efficiency but also reduces wear and tear on the system, leading to fewer breakdowns and lower maintenance costs. It's a cost-effective and straightforward maintenance task that can make a big difference in the pump's performance and longevity.

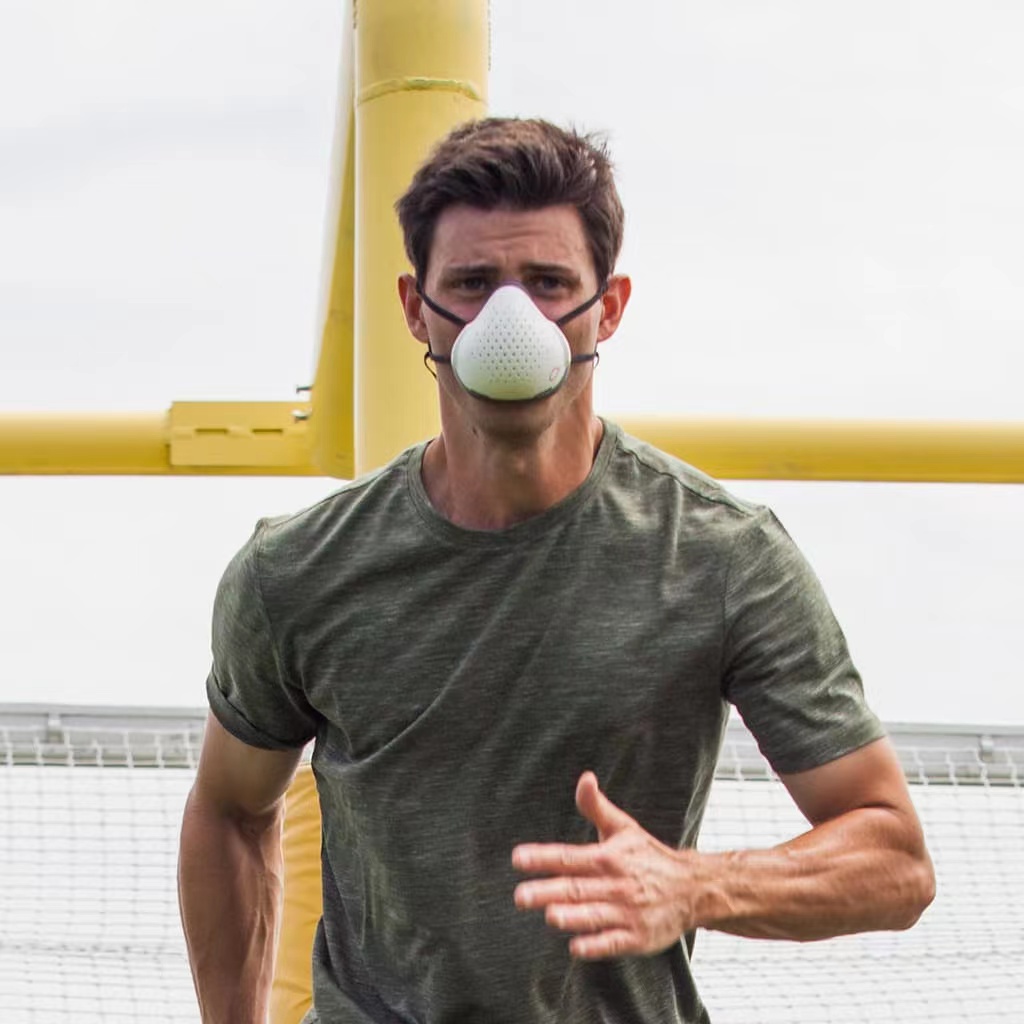

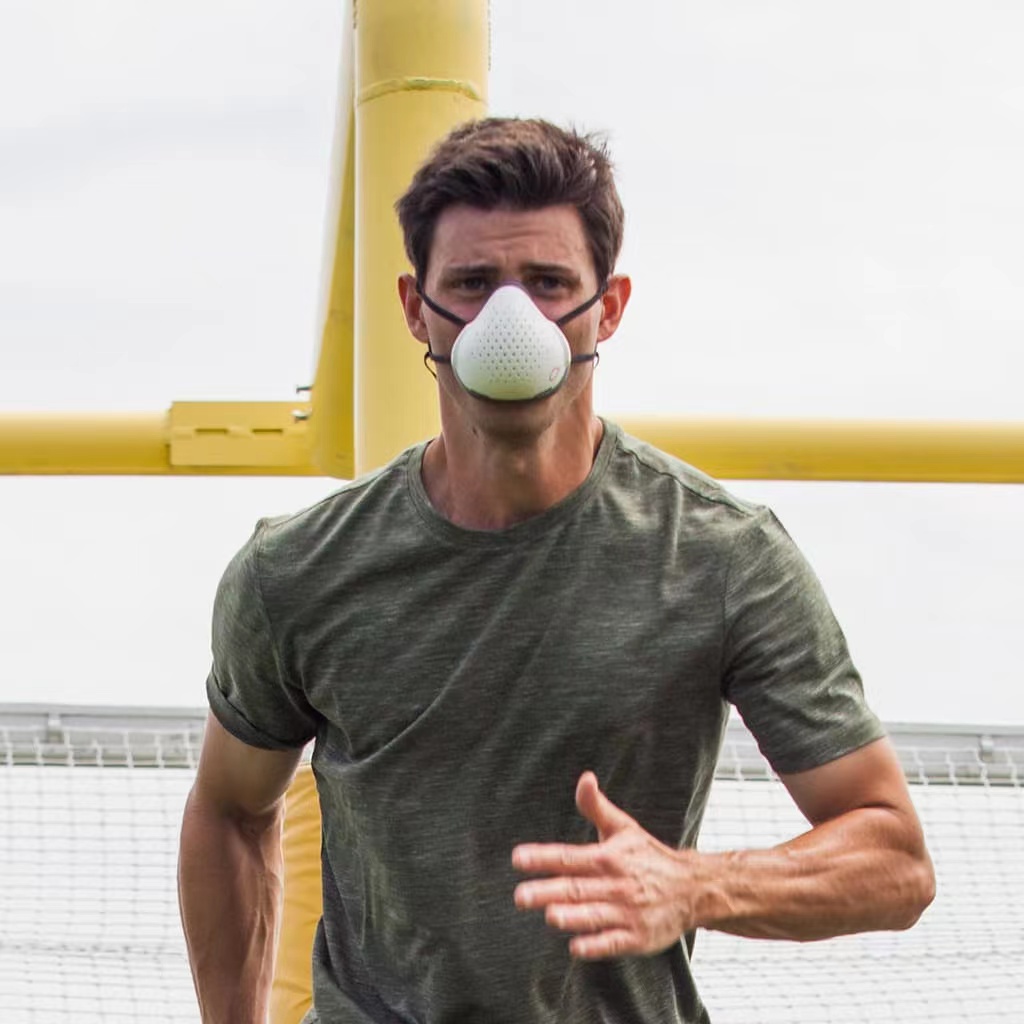

Functional liquid silicone rubber

Functional Liquid Silicone Rubber is a high-performance material designed to meet various specialized needs, featuring functions such as anti-fungal, antibacterial, and anti-static properties. This material not only offers excellent elasticity and durability but also maintains stable performanceElectrical Insulation, UV Resistance, Tensile Strength, Antistatic

Ninja Silicone , https://www.ninjasilicone.com