In a recent study, Boiler Room Consulting (BRC), an independent advisory firm, explored the potential for reducing greenhouse gas (GHG) emissions, particularly CO2, by boosting boiler inspections with the help of Flyability's collision-resistant inspection drones. The results were remarkable.

BRC discovered that increasing the frequency of boiler inspections, backed by Flyability drones, could potentially cut CO2 emissions by up to 649 metric tons annually.

Read further to discover how this was achieved.

### Enhanced Boiler Inspections = Lower Emissions

Most boiler inspections currently occur annually. This means that issues within the boiler might remain unnoticed for extended periods.

While these issues may not immediately affect the boiler's lifespan, they can still lead to leaks and other emissions that harm the environment.

By conducting inspections more frequently, companies can spot problems causing harmful emission leaks early and take corrective measures. Frequent inspections can also help companies save money by improving maintenance on costly assets like boilers and pressure vessels, thereby extending their lifespan.

### Why Aren't Boiler Inspections Done More Often?

Boiler inspections are expensive.

In a standard inspection, inspectors physically enter the boiler to conduct a thorough visual check, examining every component visually to assess its condition.

Since many boilers are large, companies need to set up scaffolding for inspectors to work safely. Building and dismantling scaffolding can be costly, ranging from thousands to tens of thousands of dollars per inspection.

The extra time required for setting up and dismantling scaffolding also leads to downtime for the boiler, which translates to lost revenue for the company—sometimes reaching hundreds of thousands of dollars daily.

Due to these high costs, most companies opt to inspect their boilers only once a year, which aligns with legal requirements in most countries.

### How Can Flyability Drones Facilitate More Frequent Inspections?

Using a drone instead of a human to gather visual data inside a boiler drastically cuts inspection costs, sometimes by up to 90% or more. This cost reduction enables companies to increase the frequency of inspections.

However, not just any drone can handle boiler inspections.

Boilers present numerous challenges for drones due to their cramped spaces and obstacles that drone blades can easily hit, causing crashes. Additionally, to collect meaningful visual data, the drone must stay stable while flying and have a light source to help inspectors understand the depth of various items on walls or ceilings being inspected, such as pitting, grooves, or welds.

Flyability drones are specifically designed for confined-space inspections like those in boilers and address all these challenges. Both the Elios and Elios 2 feature a protective cage, allowing the drone to collide and continue flying, making them ideal for boiler inspections.

Watch this video to see a boiler inspection conducted with the Elios 2:

### How Boiler Room Consulting Assessed the Environmental Impact of Increased Inspections

BRC wanted to verify the hypothesis that more frequent inspections could reduce the total amount of CO2 a boiler emits.

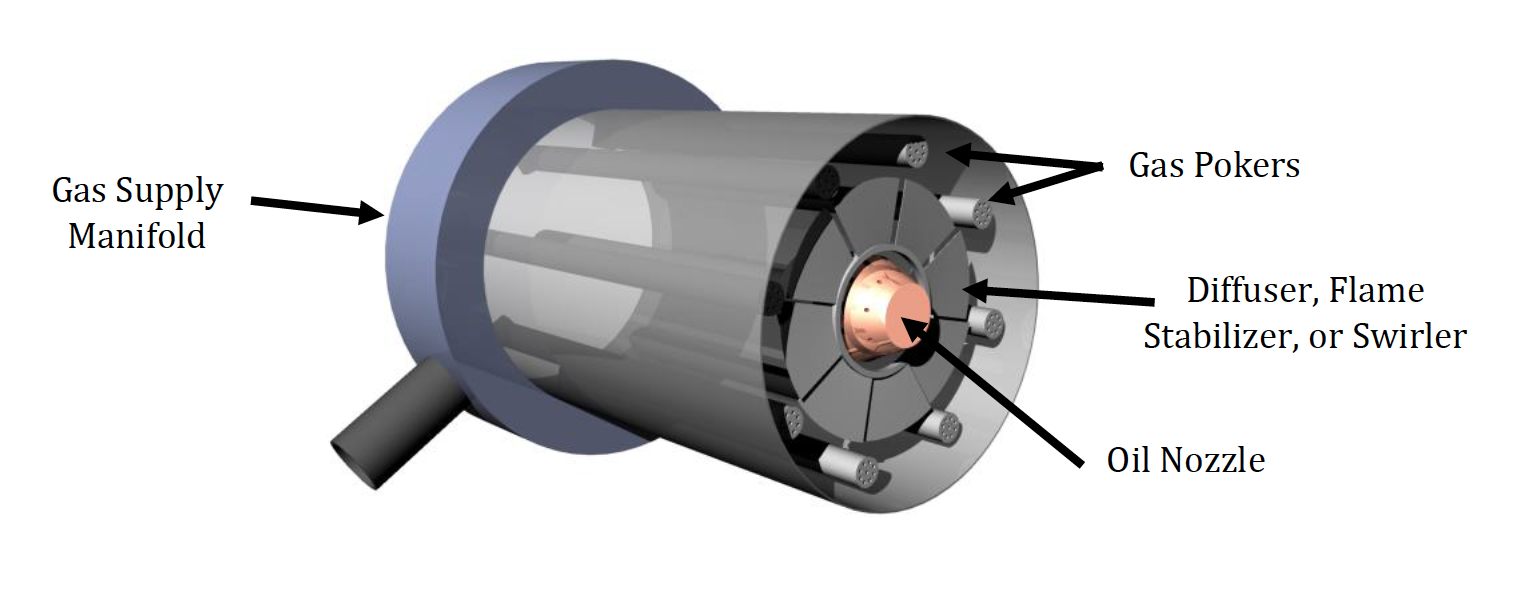

To do this, they decided to focus on the boiler's combustion head.

The combustion head was selected because combustion head malfunctions are known to lead to elevated CO production, which increases CO2 emissions, and because combustion head issues can develop gradually without immediate noticeable effects requiring urgent maintenance.

### BRC’s Combustion Head Experiment

#### Hypothesis to Test

A damaged combustion head will cause a boiler to produce higher CO2 emissions.

A faulty combustion head can generate a higher level of CO in the boiler’s flue gases. This high level of CO negatively impacts the boiler's combustion efficiency, leading to a rise in CO2 emissions.

#### Questions to Answer

1. Does a damaged combustion head increase CO2 emissions?

2. If so, by how much?

3. Are emissions increased differently based on the type of fuel?

4. Could more frequent inspections identify a damaged combustion head before it causes an increase in CO2 emissions?

#### Testing the Theory

The boiler used in BRC's study was a standard 150,000 lb per hour, 350 PSIG industrial watertube (IWT) steam boiler.

BRC examined three different fuels within the boiler—Natural Gas, #2 fuel oil, and #6 fuel oil with typical carbon, hydrogen, oxygen, and sulfur contents and the associated gross calorific heating values.

For each fuel type, BRC compared the flue gases in the boiler with a combustion head in good condition versus one that was faulty.

The findings were striking.

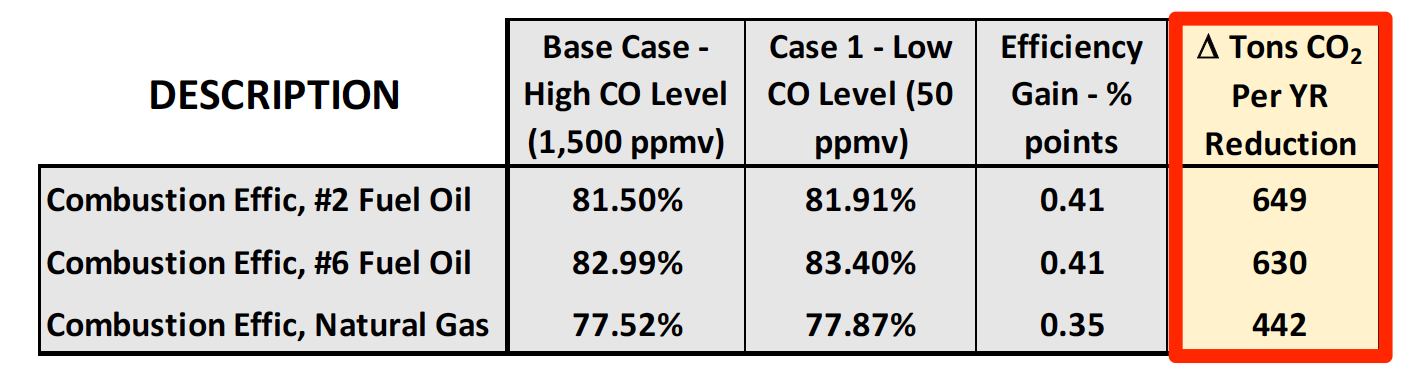

Even though the faulty combustion head only caused a loss in overall boiler efficiency of between .35% and .41%, the corresponding CO2 emissions rose by between 442 and 649 metric tons annually.

#### Cause of Increased CO2 Emissions

A malfunctioning combustion head raises CO levels in the boiler’s flue gases, reducing combustion efficiency.

In the chart above, you can see that the Base Case (the faulty combustion head) emitted 1,500 ppmv (Parts Per Million by Volume) of CO into the boiler, whereas the combustion head in good condition released only 50 ppmv of CO into the boiler.

The extra CO released into the boiler by the faulty combustion head meant the boiler needed more energy to maintain regular operations. This increase in energy usage represents a loss of efficiency—shown in the chart as a .35% to .41% drop—and results in higher CO2 emissions.

### Answers to BRC’s Questions

1. Does a damaged combustion head increase CO2 emissions? **Yes**.

2. If so, by how much? **Anywhere from 442 to 649 metric tons per year, depending on the type of fuel**.

3. Are emissions increased differently for different types of fuel? **Yes—see above**.

4. Could more frequent inspections identify a damaged combustion head before it causes an increase in CO2 emissions? **Yes. More frequent inspections increase the likelihood of detecting combustion head failure, thereby reducing the potential for increased CO2 emissions**.

### Conclusion

BRC concluded that using Flyability's collision-tolerant drones for more frequent inspections could reduce CO2 emissions by 442 to 649 metric tons annually—a substantial decrease, and this is just for a single boiler.

It’s important to note that BRC focused only on one potential type of damage.

A lot can go wrong in a year, especially within an asset exposed to such extreme temperature fluctuations, and other kinds of damage could also lead to a boiler emitting harmful substances.

“The use of collision-tolerant drone technology makes more frequent inspections feasible by simplifying the process, eliminating potential safety risks for personnel, and reducing overall costs, including operational expenses.â€

- From BRC’s final report

As noted in BRC's report, there are additional benefits for companies to conduct more inspections.

Besides cutting the release of GHGs and other harmful substances, using a drone instead of a person for inspections in confined spaces keeps workers out of potentially hazardous situations.

Increased inspections can also save companies money.

From a financial standpoint, enhancing boiler efficiency will lead to savings for the company by lowering operating costs and potentially extending the boiler's lifespan.

Tungsten Alloy Military,Tungsten Military,Tungsten Alloys Ring,Tungsten Alloy Blank Cube

Zhuzhou Jiuding Metal Technology Co., Ltd. , https://www.zztungstenheavyalloy.com