Monitoring Stockpiles at a Cement Plant with the Elios 3

The Elios 3 has revolutionized the way we monitor stockpiles at a cement plant. Not only did it cut down on risks and inspection times, but it also significantly improved the accuracy of our data. Here's how it works.

Key Benefits of the Elios 3

|

Safety First Thanks to the Elios 3, workers no longer have to climb on top of stockpiles with a GNSS rover. This not only improves safety but also eliminates the risks of falls or stockpile collapses. It's a game-changer for us! |

Lightning-Fast Inspections With the Elios 3, we can now monitor 30 different stockpiles in just 7-8 flights, completing all data collection in under two hours. That’s a massive improvement compared to the old methods! |

|

Consistent Scalability These monthly stockpile surveys with the Elios 3 cover piles ranging from several hundred cubic meters to over 10,000 cubic meters. It's a scalable solution that meets our evolving needs perfectly. Â |

Precision Redefined The Elios 3’s LiDAR scans create detailed point clouds and volume calculations in CloudCompare. These measurements are incredibly precise, often accurate to within a centimeter. No more eyeballing estimates!  |

Effective stockpile management is crucial for the operational efficiency of any industrial plant. An inaccurate estimate of materials can lead to production halts, causing costly downtime and unnecessary delays. However, managing stockpiles comes with its own set of challenges:

-

Accurate measurements can be difficult and dangerous, especially when using traditional methods like climbing over piles with a GNSS rover. Falls or material movement pose serious risks.

-

Each site is unique, requiring either one-off measurements or regular monitoring. There’s no one-size-fits-all solution here.

-

Efficiency is key. Stockpile surveys mustn’t disrupt other operations or slow down associated work.

Revolutionizing Stockpile Measurement with Drones

InspecDrone, a German-based drone service provider founded in 2018 by Simon and Susanne Kumm, specializes in helping businesses across industries like cement plants, metal processing, power generation, waste to energy, and woodworking. Their mission? To enhance safety, reduce downtime, and provide critical data through drone inspections.

Inspecting stockpiles safely from a distance

One of their clients runs a cement plant that has numerous stockpiles needing regular measurement. Previously, this client relied on visual estimates and manual GNSS measurements to decide when to order new materials. They sought a more reliable and precise method.

The goal was simple yet ambitious: Use the Elios 3 drone to measure stockpiles while achieving three main objectives:

-

Track on-site materials in bunkers and piles more accurately, using this data to plan deliveries and quantities.

-

Eliminate the need for people to walk on top of piles with a GPS rover, which is both risky and inefficient.

-

Obtain accurate measurements that can be consistently quantified.

InspecDrone owns multiple drones and chose the Elios 3 with its specialized LiDAR payload due to its precision in volume measurement and ability to handle mixed locations both inside and outside storage bunkers.

Monitoring Cement Stockpiles with the Elios 3

InspecDrone visited the site and evaluated the area. There were several stockpiles, some inside a bunker and others stored outdoors. The Elios 3’s ability to fly in confined spaces and its collision-tolerance reassured the team. By using this drone, they achieved one of their primary goals—eliminating the need for people to walk over the piles. The drone gathered all necessary data efficiently.

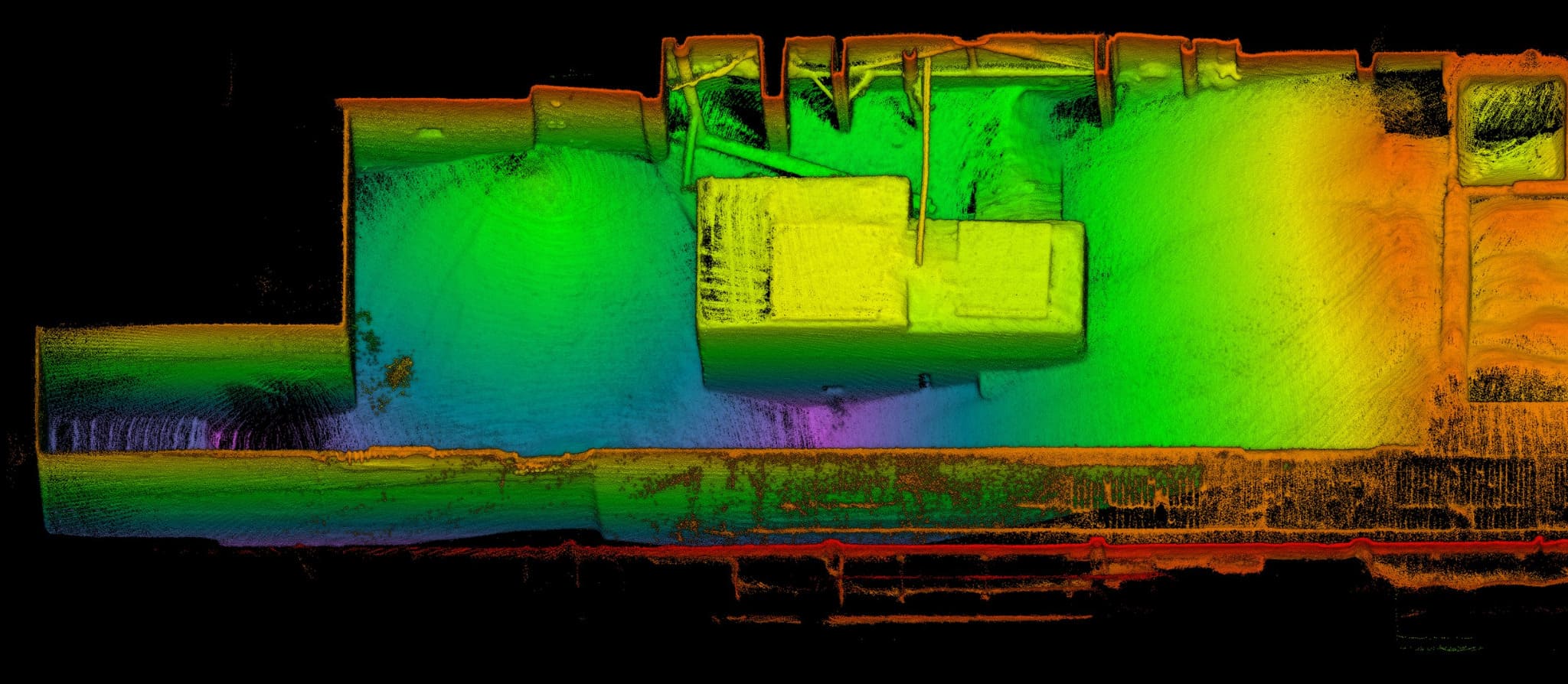

InspecDrone used the Elios 3 to precisely quantify stockpile volumes

After flying the drone around the stockpiles, the team processed the results in CloudCompare. The storage area had an unusual layout, so Simon took care to adjust his post-processing accordingly. Once done, he began measuring stockpile volumes with CloudCompare. The final results were shared with the client.

Regular Drone Surveys for Stockpiles

Following this initial survey, the cement plant requested InspecDrone return monthly to measure their stockpiles. The Elios 3’s results proved highly accurate and provided sufficient detail for the plant managers to plan refills and assess current stock conditions.

Today, the entire inventory of the site takes just 7 or 8 flights with the Elios 3 to cover all 30 stockpiles and bunkers, ranging from a few hundred cubic meters to 10,000 cubic meters. Each month, InspecDrone visits the site to conduct surveys and compile reports for the cement plant managers.

LiDAR point clouds depict stockpile volumes with the Elios 3

Moreover, by creating accurate models of the bunkers, we can determine their dimensions and available space. Often, there are large amounts of unusable material (dead stock). With the Elios 3, InspecDrone can quantify these stockpiles and use them as a baseline for future measurements—whether adding to the pile or calculating remaining storage capacity.

Frequent Drone Inspection Surveys

The combination of LiDAR technology from the Elios 3 and its innovative design makes it an ideal alternative to traditional stockpile surveys. It surpasses "eyeball" estimates in terms of precision. With the LiDAR stabilization, InspecDrone is expanding its services to inspect the interiors of cement assets like silos. Fast inspections with the drone ensure safer operations while cutting downtime and costs. Through these efforts, InspecDrone achieves the goals set for stockpile surveys: accurate results that facilitate better planning and eliminate the need for climbing over material piles. As the Elios 3 continues to improve in accuracy and expand its capabilities, InspecDrone anticipates uncovering new and exciting workflows.

The most precise surveys with the Elios 3 are conducted using the surveying payload.

Middle Speed Flat Film Tape Extruder

We have strong technical force, a perfect CAD network, CAPP networks and a CAD development system, with all kinds of large-scale precise equipment, high-medium machining equipment, testing equipment, advanced production technology, a quality assurance system and steady product quality. The "Three-dragon" brand complete set of equipment for Middle Speed Flat Film Tape Extruder is sold throughout the country and exported to overseas markets, and now it covers more than 30 countries and regions, such as Russia, Vietnam, Indonesia, Malaysia, Bangladesh, Uzbekistan, Ethiopia, Congo, Nigeria, Syria, etc.

Middle Speed Flat Film Tape Extruder,Pp Woven Extruder Tape Produce Machine,Pp Woven Extruder Tape Machine,Woven Extruder Tape Machine

Zhejiang Sanlong Universal Machinery Co.,Ltd. , https://www.sanlongco.com