# Leveraging the Elios 3 Drone for Stockpile Monitoring at a Cement Plant

The Elios 3 has proven to be a game-changer in streamlining stockpile monitoring at a cement plant, significantly reducing risks and cutting down inspection times while boosting data accuracy. Here's how it has transformed operations.

## Key Benefits at a Glance

| Aspect | Description |

|---------------|-----------------------------------------------------------------------------------------------|

| **Safety** | The Elios 3 eliminates the need for workers to physically climb stockpiles, thus minimizing risks like falls or cave-ins. |

| **Efficiency**| A single mission comprising 7-8 flights can efficiently cover 30 stockpiles, completing data collection in under two hours. |

| **Scalability**| Monthly surveys are now standard practice, accommodating stockpiles ranging from several hundred cubic meters to over 10,000 cubic meters. |

| **Precision** | The LiDAR scans from the Elios 3 allow for detailed point cloud analysis and volume calculations in software like CloudCompare, offering centimeter-level accuracy. |

Proper stockpile management is crucial for maintaining operational efficiency at any industrial facility. An inaccurate assessment of materials can lead to unexpected shortages, halting production entirely. This results in costly downtime, wasted time, and frustration for all stakeholders involved.

Challenges in managing stockpiles include:

- **Measurement Challenges**: Traditional methods require personnel to manually climb stockpiles with GNSS devices, posing significant safety risks.

- **Customized Solutions**: Each site has unique requirements, necessitating tailored approaches rather than a one-size-fits-all solution.

- **Operational Efficiency**: Stockpile surveys must be conducted quickly without disrupting ongoing activities.

## Introducing a Smarter Approach with Drones

InspecDrone, a German-based drone service provider established in 2018 by Simon and Susanne Kumm, specializes in helping industries like cement production enhance safety, cut costs, and generate critical data. Their clientele spans sectors including cement plants, metal processing, power generation, waste-to-energy facilities, and woodworking.

*Drone inspections can be performed safely from a distance.*

One of InspecDrone's clients operates a cement plant that houses numerous stockpiles requiring routine measurement. Previously, the plant relied on visual estimates and manual GNSS readings to decide when to order new supplies. Seeking greater reliability and precision, they turned to the Elios 3 drone.

The goals were straightforward:

- Accurately track materials in storage bunkers and piles to optimize delivery schedules.

- Eliminate the hazardous practice of walking on stockpiles with GNSS equipment.

- Obtain precise measurements that could be consistently verified.

Given the Elios 3's exceptional LiDAR payload for volumetric precision and its ability to operate both indoors and outdoors, it was the ideal choice.

## Monitoring Cement Stockpiles with the Elios 3

Upon visiting the site, InspecDrone evaluated the layout, noting multiple stockpiles—some housed indoors while others remained outdoors. The Elios 3’s collision-resistant design and indoor flight capability gave the team confidence to navigate confined spaces. By deploying the drone, they achieved one of their primary objectives: removing humans from the equation entirely.

*Drone inspections can be performed safely from a distance.*

One of InspecDrone's clients operates a cement plant that houses numerous stockpiles requiring routine measurement. Previously, the plant relied on visual estimates and manual GNSS readings to decide when to order new supplies. Seeking greater reliability and precision, they turned to the Elios 3 drone.

The goals were straightforward:

- Accurately track materials in storage bunkers and piles to optimize delivery schedules.

- Eliminate the hazardous practice of walking on stockpiles with GNSS equipment.

- Obtain precise measurements that could be consistently verified.

Given the Elios 3's exceptional LiDAR payload for volumetric precision and its ability to operate both indoors and outdoors, it was the ideal choice.

## Monitoring Cement Stockpiles with the Elios 3

Upon visiting the site, InspecDrone evaluated the layout, noting multiple stockpiles—some housed indoors while others remained outdoors. The Elios 3’s collision-resistant design and indoor flight capability gave the team confidence to navigate confined spaces. By deploying the drone, they achieved one of their primary objectives: removing humans from the equation entirely.

*The Elios 3 provided precise quantification of stockpile volumes.*

Following drone flights around the stockpiles, the team processed data in CloudCompare. Due to the unique geometry of the storage area, Simon carefully adjusted his post-processing techniques. Once the stockpile volumes were measured, the findings were shared with the client.

## Regular Drone Surveys for Enhanced Management

Impressed by the initial results, the cement plant requested InspecDrone return monthly to assess stockpiles. The Elios 3 produced highly accurate data, providing sufficient detail for plant managers to schedule refills and monitor stock conditions effectively.

Today, the entire inventory of the site can be captured in just 7-8 flights using the Elios 3, encompassing 30 stockpiles and bunkers ranging from hundreds to thousands of cubic meters. Each month, InspecDrone visits the plant to conduct surveys and deliver comprehensive reports.

*The Elios 3 provided precise quantification of stockpile volumes.*

Following drone flights around the stockpiles, the team processed data in CloudCompare. Due to the unique geometry of the storage area, Simon carefully adjusted his post-processing techniques. Once the stockpile volumes were measured, the findings were shared with the client.

## Regular Drone Surveys for Enhanced Management

Impressed by the initial results, the cement plant requested InspecDrone return monthly to assess stockpiles. The Elios 3 produced highly accurate data, providing sufficient detail for plant managers to schedule refills and monitor stock conditions effectively.

Today, the entire inventory of the site can be captured in just 7-8 flights using the Elios 3, encompassing 30 stockpiles and bunkers ranging from hundreds to thousands of cubic meters. Each month, InspecDrone visits the plant to conduct surveys and deliver comprehensive reports.

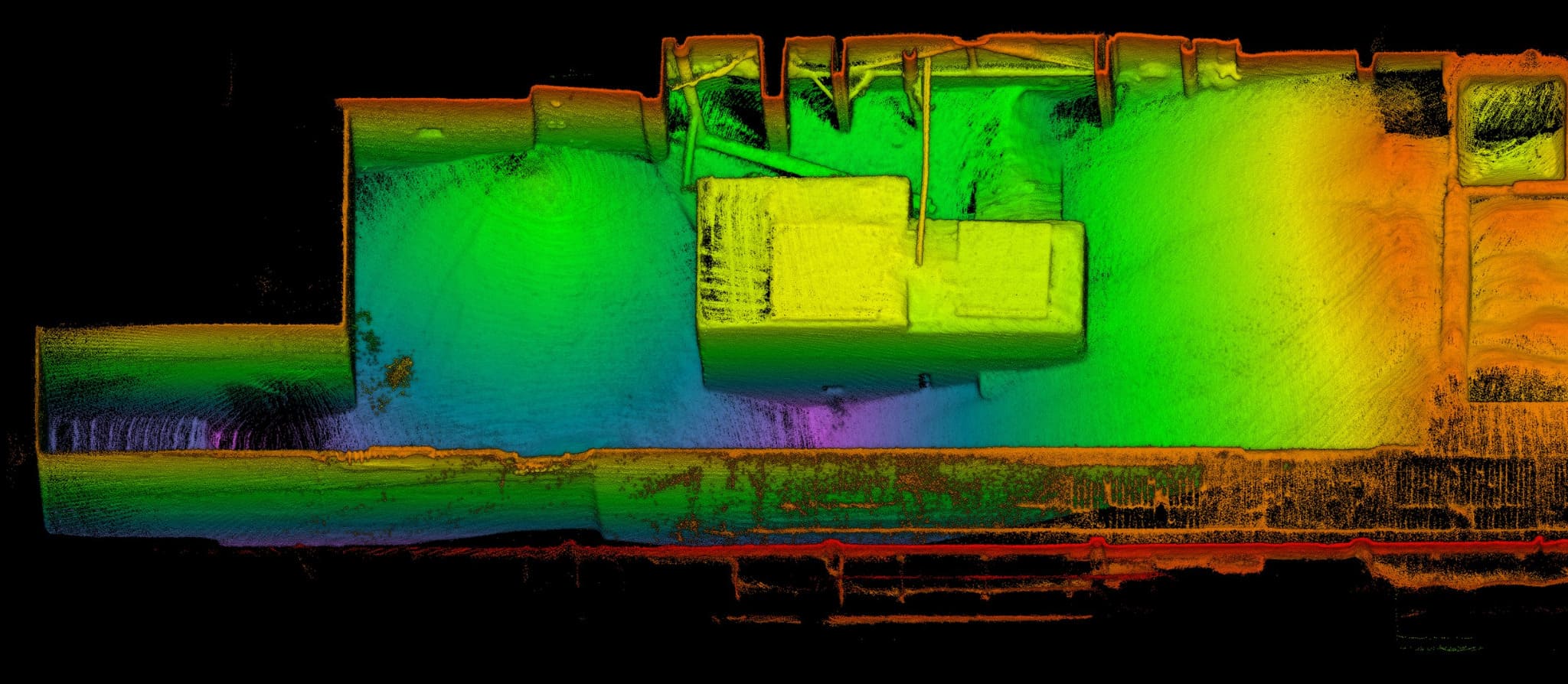

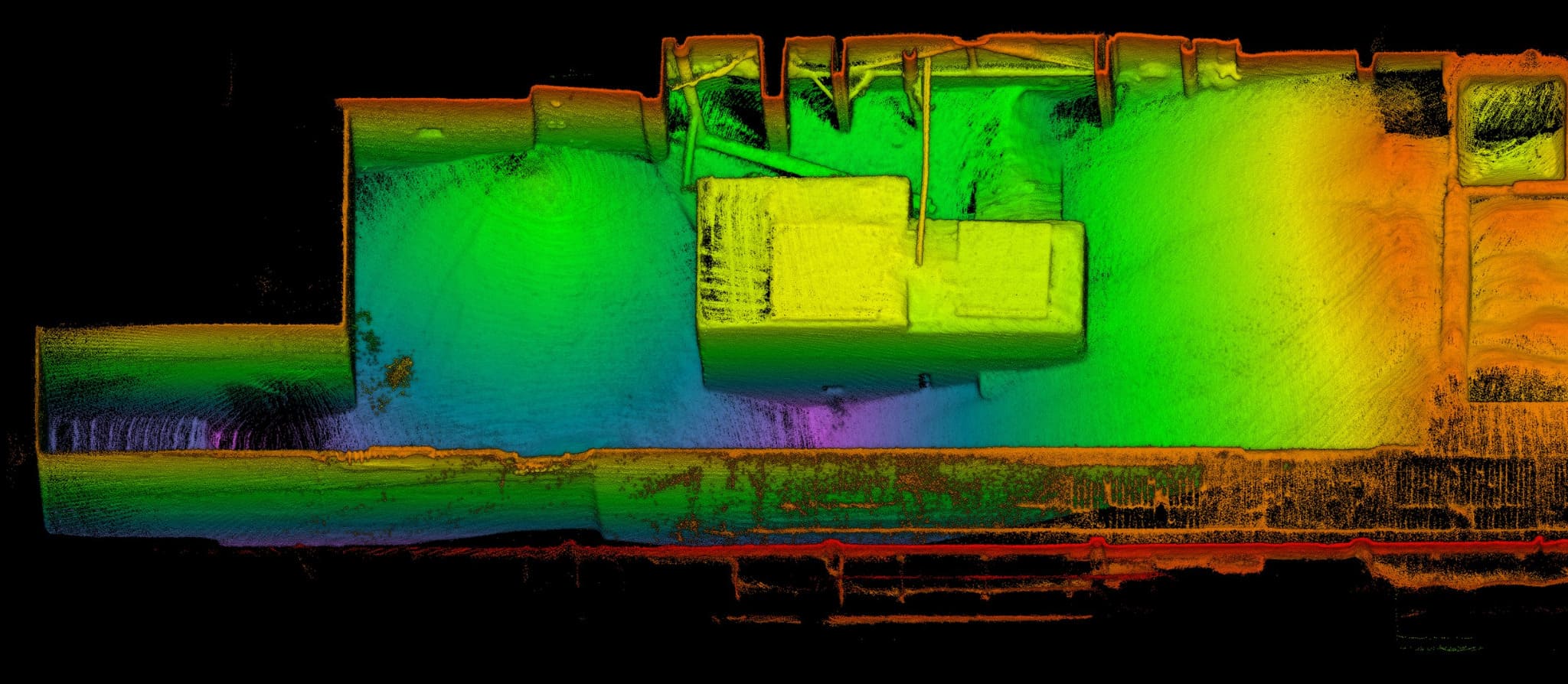

*LiDAR point clouds visualize stockpile volumes.*

Thanks to these detailed models, the team can also evaluate unused material (dead stock) and use it as a baseline for future measurements, aiding in space optimization or addition to existing stockpiles.

## Expanding Drone Inspection Services

The integration of LiDAR technology with the Elios 3’s innovative design has established it as a superior alternative to conventional stockpile surveys. Its accuracy far surpasses visual estimation, ensuring reliable outcomes.

With LiDAR stabilization, InspecDrone is broadening its offerings to include internal inspections of cement assets such as silos. Fast drone inspections ensure safer operations while reducing downtime and costs. Achieving the original goals of accurate results facilitating better planning and keeping workers off hazardous piles, InspecDrone anticipates unlocking even more advanced workflows as the Elios 3 continues to evolve.

The highest accuracy is attained with the Elios 3's surveying payload, offering unparalleled insights into stockpile management.

*LiDAR point clouds visualize stockpile volumes.*

Thanks to these detailed models, the team can also evaluate unused material (dead stock) and use it as a baseline for future measurements, aiding in space optimization or addition to existing stockpiles.

## Expanding Drone Inspection Services

The integration of LiDAR technology with the Elios 3’s innovative design has established it as a superior alternative to conventional stockpile surveys. Its accuracy far surpasses visual estimation, ensuring reliable outcomes.

With LiDAR stabilization, InspecDrone is broadening its offerings to include internal inspections of cement assets such as silos. Fast drone inspections ensure safer operations while reducing downtime and costs. Achieving the original goals of accurate results facilitating better planning and keeping workers off hazardous piles, InspecDrone anticipates unlocking even more advanced workflows as the Elios 3 continues to evolve.

The highest accuracy is attained with the Elios 3's surveying payload, offering unparalleled insights into stockpile management.

*Drone inspections can be performed safely from a distance.*

One of InspecDrone's clients operates a cement plant that houses numerous stockpiles requiring routine measurement. Previously, the plant relied on visual estimates and manual GNSS readings to decide when to order new supplies. Seeking greater reliability and precision, they turned to the Elios 3 drone.

The goals were straightforward:

- Accurately track materials in storage bunkers and piles to optimize delivery schedules.

- Eliminate the hazardous practice of walking on stockpiles with GNSS equipment.

- Obtain precise measurements that could be consistently verified.

Given the Elios 3's exceptional LiDAR payload for volumetric precision and its ability to operate both indoors and outdoors, it was the ideal choice.

## Monitoring Cement Stockpiles with the Elios 3

Upon visiting the site, InspecDrone evaluated the layout, noting multiple stockpiles—some housed indoors while others remained outdoors. The Elios 3’s collision-resistant design and indoor flight capability gave the team confidence to navigate confined spaces. By deploying the drone, they achieved one of their primary objectives: removing humans from the equation entirely.

*Drone inspections can be performed safely from a distance.*

One of InspecDrone's clients operates a cement plant that houses numerous stockpiles requiring routine measurement. Previously, the plant relied on visual estimates and manual GNSS readings to decide when to order new supplies. Seeking greater reliability and precision, they turned to the Elios 3 drone.

The goals were straightforward:

- Accurately track materials in storage bunkers and piles to optimize delivery schedules.

- Eliminate the hazardous practice of walking on stockpiles with GNSS equipment.

- Obtain precise measurements that could be consistently verified.

Given the Elios 3's exceptional LiDAR payload for volumetric precision and its ability to operate both indoors and outdoors, it was the ideal choice.

## Monitoring Cement Stockpiles with the Elios 3

Upon visiting the site, InspecDrone evaluated the layout, noting multiple stockpiles—some housed indoors while others remained outdoors. The Elios 3’s collision-resistant design and indoor flight capability gave the team confidence to navigate confined spaces. By deploying the drone, they achieved one of their primary objectives: removing humans from the equation entirely.

*The Elios 3 provided precise quantification of stockpile volumes.*

Following drone flights around the stockpiles, the team processed data in CloudCompare. Due to the unique geometry of the storage area, Simon carefully adjusted his post-processing techniques. Once the stockpile volumes were measured, the findings were shared with the client.

## Regular Drone Surveys for Enhanced Management

Impressed by the initial results, the cement plant requested InspecDrone return monthly to assess stockpiles. The Elios 3 produced highly accurate data, providing sufficient detail for plant managers to schedule refills and monitor stock conditions effectively.

Today, the entire inventory of the site can be captured in just 7-8 flights using the Elios 3, encompassing 30 stockpiles and bunkers ranging from hundreds to thousands of cubic meters. Each month, InspecDrone visits the plant to conduct surveys and deliver comprehensive reports.

*The Elios 3 provided precise quantification of stockpile volumes.*

Following drone flights around the stockpiles, the team processed data in CloudCompare. Due to the unique geometry of the storage area, Simon carefully adjusted his post-processing techniques. Once the stockpile volumes were measured, the findings were shared with the client.

## Regular Drone Surveys for Enhanced Management

Impressed by the initial results, the cement plant requested InspecDrone return monthly to assess stockpiles. The Elios 3 produced highly accurate data, providing sufficient detail for plant managers to schedule refills and monitor stock conditions effectively.

Today, the entire inventory of the site can be captured in just 7-8 flights using the Elios 3, encompassing 30 stockpiles and bunkers ranging from hundreds to thousands of cubic meters. Each month, InspecDrone visits the plant to conduct surveys and deliver comprehensive reports.

*LiDAR point clouds visualize stockpile volumes.*

Thanks to these detailed models, the team can also evaluate unused material (dead stock) and use it as a baseline for future measurements, aiding in space optimization or addition to existing stockpiles.

## Expanding Drone Inspection Services

The integration of LiDAR technology with the Elios 3’s innovative design has established it as a superior alternative to conventional stockpile surveys. Its accuracy far surpasses visual estimation, ensuring reliable outcomes.

With LiDAR stabilization, InspecDrone is broadening its offerings to include internal inspections of cement assets such as silos. Fast drone inspections ensure safer operations while reducing downtime and costs. Achieving the original goals of accurate results facilitating better planning and keeping workers off hazardous piles, InspecDrone anticipates unlocking even more advanced workflows as the Elios 3 continues to evolve.

The highest accuracy is attained with the Elios 3's surveying payload, offering unparalleled insights into stockpile management.

*LiDAR point clouds visualize stockpile volumes.*

Thanks to these detailed models, the team can also evaluate unused material (dead stock) and use it as a baseline for future measurements, aiding in space optimization or addition to existing stockpiles.

## Expanding Drone Inspection Services

The integration of LiDAR technology with the Elios 3’s innovative design has established it as a superior alternative to conventional stockpile surveys. Its accuracy far surpasses visual estimation, ensuring reliable outcomes.

With LiDAR stabilization, InspecDrone is broadening its offerings to include internal inspections of cement assets such as silos. Fast drone inspections ensure safer operations while reducing downtime and costs. Achieving the original goals of accurate results facilitating better planning and keeping workers off hazardous piles, InspecDrone anticipates unlocking even more advanced workflows as the Elios 3 continues to evolve.

The highest accuracy is attained with the Elios 3's surveying payload, offering unparalleled insights into stockpile management.Printing Machine,Printer Machine,Roll To Roll Printing Machine,Piece By Piece Printer

Zhejiang Sanlong Universal Machinery Co.,Ltd. , https://www.sanlongco.com