# What Is Industrial Radiography Used For?

Radiography refers to the use of radiation to generate images of objects that cannot be seen with the naked eye. In the medical field, radiography helps create images that reveal the internal conditions of the human body, such as bones, tissues, or organs.

In industrial settings, radiography plays a crucial role in detecting flaws that might not be visible to the naked eye. Inspectors rely on industrial radiography to ensure the safety and compliance of critical assets.

In this guide, we will explore the various applications of industrial radiography across different industries, focusing particularly on its role in inspections. For information on how radiography is applied in medical contexts, I recommend checking out this article by the FDA.

[Industrial radiography is just one of many non-destructive testing (NDT) methods used by inspectors. To learn more about NDT, read this comprehensive guide.]

[Note: Industrial radiography is also sometimes referred to as industrial radiology.]

*Radiographic testing used on a pipe*

## Industrial Radiography

Industrial radiography (IR) involves using radiation to inspect the integrity and structure of materials. Both gamma rays and X-rays are employed in industrial radiography because they can penetrate many substances, enabling inspectors to perform internal examinations without altering the object being examined.

Industrial radiography serves two primary functions:

- **Manufacturers** use industrial radiography to identify defects within the materials they utilize.

- **Inspectors** leverage industrial radiography to detect flaws in industrial assets, ensuring their safety and compliance with mandated inspection standards.

Industries such as automobile manufacturers and airplane builders commonly employ radiographic testing to examine vehicle and aircraft components.

[Related read: What Is a Dosimeter and Why Is It Important?]

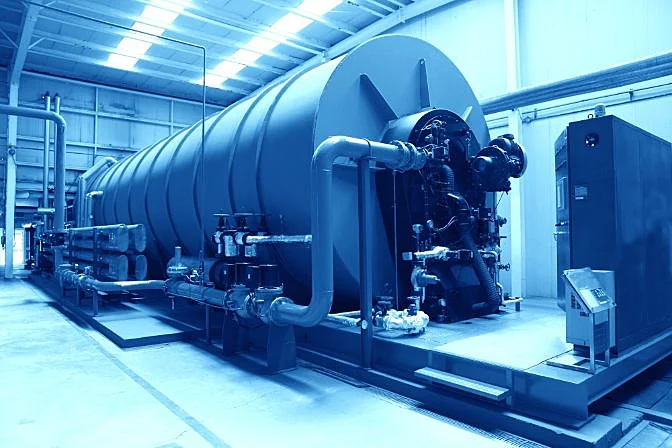

Industries involved in inspections, including Oil and Gas operations and Power Generation, frequently use radiography to assess boilers, welding, and piping systems.

*An industrial boiler*

### Non-Destructive vs. Destructive Testing

A side note: Inspection methods like radiography, which allow for examining a material without altering it, are known as non-destructive testing (NDT) methods due to their non-invasive nature. In contrast, destructive testing methods require sampling or altering the substance to gather information. For instance, applying a chemical mixture to paint to detect lead changes the paint, classifying it as a destructive testing method.

### A Note on Safety in Industrial Radiography

The radiation used in industrial radiography originates from either a radiation-producing machine or radioactive material sources. While industrial radiography is a powerful tool for assessing the internal structure of materials, it poses risks if not handled properly.

Industrial radiographers experience the highest rate of radiation-related accidents compared to other radiation-related occupations. Given these hazards, stringent procedures are in place and enforced by law for industrial radiography. For more details, see the "Careers and Salary" section below.

## Radiographic Testing—How Does It Work?

Radiographic testing involves using radiation to inspect or test materials for evaluation purposes. Here's how it works:

1. **Align radiation**: An inspector directs radiation (gamma rays or X-rays) toward the object to be inspected.

2. **Position the detector**: On the opposite side of the object, the inspector places a detector aligned with the radiation beam.

3. **Record data**: The detector records the radiation passing through the object.

4. **Analyze results**: The recorded data is analyzed to interpret the findings from the test.

The key advantage lies in the analysis. At a high level, industrial radiographers look for areas where less or more radiation passes through the object. Less radiation indicates thicker material, suggesting it is likely in good condition. Conversely, more radiation suggests thinner areas, possibly indicating cracks or flaws.

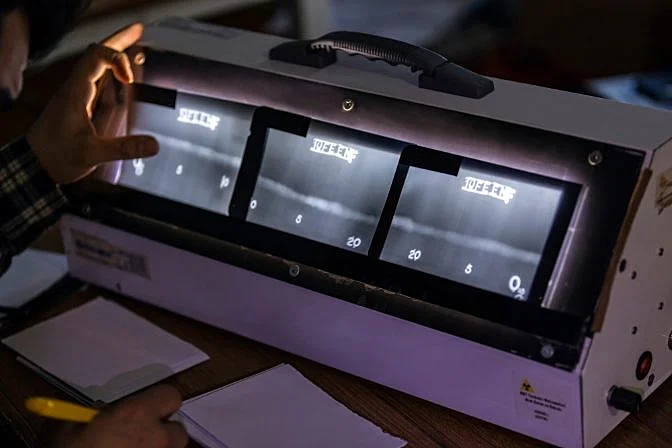

The images produced from radiographic testing are called radiographs. Nowadays, most radiography cameras record digital images, though earlier techniques used film.

## Industrial Radiography Equipment

The two main types of industrial radiography equipment utilize the two types of radiation we've discussed—X-rays and gamma rays.

### Gamma Rays Industrial Uses & Equipment

Equipment using gamma rays harnesses radiation emanating from radioactive material within the device. This type of equipment is smaller, making it suitable for use in confined spaces. However, it does not require electricity and cannot be switched off—it constantly emits radiation. The only way to protect workers is by enclosing it in a specialized metal casing.

### X-Rays Industrial Uses & Equipment

Equipment using X-rays is typically larger, making it ideal for radiographic testing in expansive environments like factories or warehouses. These devices run on electricity and can be turned on and off, ensuring they are safe when inactive (no protective shielding is necessary).

Due to the potential dangers of radiation, the use, ownership, and transportation of radiography equipment require a license in the U.S. and many other regions. In the U.S., the U.S. Nuclear Regulatory Commission establishes and oversees licensing requirements. Learn more [here](link-to-source).

## Careers and Salary in Industrial Radiography

Interested in becoming an industrial radiographer? Here’s what you need to enter the field:

- A high school diploma

- A certificate from an industrial radiographer training program

### What Is an Industrial Radiographer?

An industrial radiographer uses radiation to conduct tests on materials, equipment, and assets to determine their soundness or presence of flaws. For asset inspections, industrial radiographers often examine large items like aboveground and underground pipelines (commonly used in the Oil and Gas industry) or other substantial machinery.

*Radiographic testing used on a weld in an aboveground pipe*

To perform this work, industrial radiographers create images using X-rays and analyze these images for defects or flaws. During this process, they must adhere to safety protocols to minimize radiation exposure.

Jobs in industrial radiography are typically full-time positions. Since the objects being tested are often large, stationary assets, radiographers must travel to job sites.

### What Does an Industrial Radiographer Salary Look Like?

According to ZipRecruiter, the national average annual salary for an industrial radiographer is approximately $54,000. Below are salaries from the top-paying industrial radiography jobs in the U.S.:

*Data provided by ZipRecruiter*

As you'll notice, your salary may vary depending on your location. Additionally, inspectors might earn more—and in some cases, significantly more—by obtaining additional certifications and gaining experience in other types of inspection work.

### Industrial Radiography Certification

In the U.S. and many other regions, certification is mandatory for performing industrial radiography work. Requirements vary by state and country but generally include:

- Hands-on training for a specified number of hours under a certified industrial radiographer

- Completion of a radiation safety course

- Passing a written examination

Some common certification types include:

- **RAM**: Certification solely for radioactive materials.

- **X-RAY**: Certification exclusively for X-ray machines.

- **Both**: Certification for both radioactive materials and X-ray machines.

In the U.S., several states have their own nationally recognized IR certification programs. Learn more [here](link-to-source).

As technology advances, we may soon be able to create full, highly detailed 3D models of the interiors of assets. These models could serve as visual records for monitoring corrosion in assets, similar to how high-quality still images and videos currently do.

## Drones and Industrial Radiography

Drones are not yet widely used in industrial radiography, but this could change in the coming years. At least one drone, the DroneX by Pacific Imaging, is equipped with an X-ray imaging system.

The DroneX is currently being used to inspect conductor sleeves on power lines. This allows inspectors to gather data about the condition of power lines without putting themselves at risk by climbing or operating a bucket truck for manual inspections.

*Photo credit: Pacific Imaging*

Based on our research, the DroneX platform is already in use for power line inspections, enabling inspectors to collect data without endangering themselves. As drone technology continues to evolve, we may see more drones equipped with X-ray imaging capabilities, expanding the boundaries of how industrial radiation can be performed.

---

This article provides an overview of industrial radiography, its applications, equipment, safety considerations, and career prospects. Stay tuned for further developments in this rapidly evolving field!

Bagging Machine With Sealing

There are many products classified in this section of Sealing by Hot-melting. They are focused on Folding Packing With Sealing by hot melting for garment at last. Attention: The following garment are applied to this auto folding packing machine. Like, garment designed with many accesories, too thick coat,suits t shirts.

All machine include the following function:

1.Within the allowable value range, the folded length and width can be adjusted as you want.

2.The machine can automatically detect the length of garment, when the garment size is different, machine can intelligently identify and automatically fold according to the first folding length, so as to ensure the uniform folding length without changing the polybag. Clothes of different sizes can be folded into uniform sizes and packed into bags.

3.Machine will calculate the number of completed pieces automatically

4.Alarm function for multiple garments can be set up.

Garment Packing Machine, Automatic Garment Bagging, Heat Seal Machine For Clothing, Heat Seal Machine For Garments

SHENZHEN LINGCHUANG ZHUOYUE TECHNOLOGY CO., LTD , https://www.lcautosz.com